The widespread adoption of the FM 4910 standard in the semiconductor and cleanroom industries stems from the significant risks associated with fires in sensitive environments. The presence of delicate equipment and volatile chemicals in this environment has the potential to cause rapid fires, leading to significant safety and damage concerns.

The widespread adoption of the FM 4910 standard in the semiconductor and cleanroom industries stems from the significant risks associated with fires in sensitive environments. The presence of delicate equipment and volatile chemicals in this environment has the potential to cause rapid fires, leading to significant safety and damage concerns. Manufacturers can significantly reduce the risk of fire by carefully selecting materials that meet FM 4910 criteria and maintaining a safer, more controlled environment.

The role of FM 4910 compliance- Be confident when choosing your FM 4910 materials.

In the highly regulated semiconductor manufacturing and cleanroom industries, ensuring the safety and quality of materials used is paramount. Complying with FM 4910 and selecting flame retardant resins that meet its criteria is critical to protecting the integrity and safety of cleanroom applications in the semiconductor and other manufacturing industries. . By choosing the right materials, industry professionals can significantly reduce the risk of fire, protect valuable equipment and maintain the highest quality and safety standards in room environments. clean and their semiconductors.

What do we expect from FM 4910 Compliant Plastics?

It is stated that “cleanroom materials must meet both criteria Fire Spread Index (FPI) and Smoke Damage Index (SDI)” (class FM 4910), but other characteristics also make them ideal for cleanroom and semiconductor applications. Include:

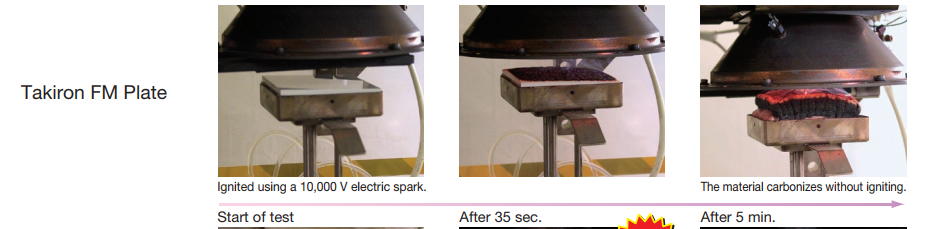

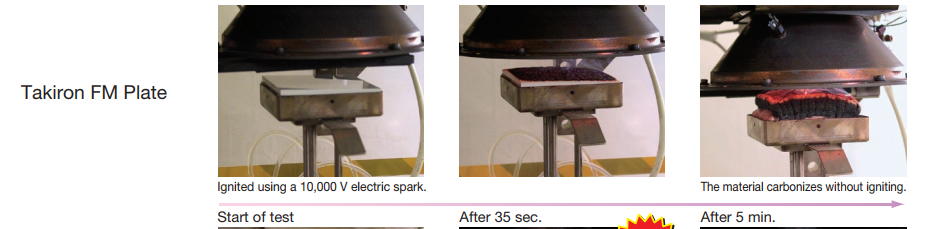

- Low Flame Spread Index: FM 4910 compliant plastics have a low flame spread index, indicating their reduced ability to ignite and burn quickly.

- Minimal smoke emissions: These materials produce minimal smoke during combustion, reducing the risk of contaminating cleanroom environments.

- High chemical resistance: FM 4910 compliant resins demonstrate exceptional resistance to chemicals commonly found in cleanroom environments, such as solvents and acids.

- Durability: These products are designed to withstand repeated use and rigorous cleaning procedures without compromising their physical properties or fire resistance.

- A significant advantage of using FM 4910 compliant materials in cleanrooms is the ability to minimize contamination risks. In the semiconductor industry, where even the smallest particle or impurity can affect the quality and functionality of microelectronic devices, maintaining low contamination levels is critical. Contamination can lead to defects in semiconductor components, affecting their performance and reliability.

We are proud to be the official agent of TAKIRON plastic company - Japan, the world's number one company in the production of fireproof plastic materials meeting FM4910 standards.

Please contact HOTLINE 0942 201 987 (Ms Huong) for advice and the best quote!

LH updated May 21